Revolutionizing Toy Car Design: Precision Mould Texturing for Enhanced Wheel Dynamics!

In the ever-evolving world of toy manufacturing, the quest for perfection meets innovation in precision mould texturing. This transformative process not only elevates the aesthetics of toy car design but also enhances the functional dynamics of their wheels. Join us as we delve into the revolution of precision mould texturing, exploring the role of mould surface textures service providers and the advanced techniques of laser printing on metals and laser engraving that are reshaping the toy car industry.

Precision Mould

Texturing: Redefining Toy Car Aesthetics

Precision mould texturing is a technique that adds intricate

patterns, textures, and designs to the surface of toy car moulds. This process

is a game-changer for toy designers, allowing them to create visually stunning

and realistic details on toy cars that were once difficult to achieve with

traditional methods.

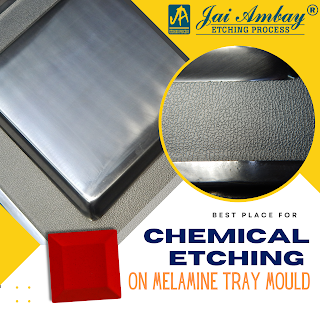

Mould

surface textures service provider specializes in applying precision mould

texturing, offering a range of patterns from fine textures to detailed designs.

This collaboration between toy manufacturers and texture service providers

ensures that each toy car boasts a unique and eye-catching appearance, setting

it apart in a competitive market.

Laser Printing on

Metals: Unleashing Design Possibilities

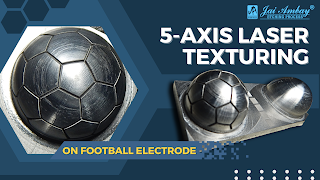

Laser printing on metals is a key component of precision

mould texturing, especially when it comes to toy car wheels. This advanced

technique allows manufacturers to imprint intricate designs and textures

directly onto metal surfaces with exceptional precision.

The precision offered by laser printing on metals is

unparalleled, enabling the creation of realistic tire treads, spoke patterns,

and other intricate wheel details. This not only enhances the visual appeal of

toy cars but also contributes to the overall authenticity and quality of the

final product. As technology continues to advance, the possibilities for laser

printing on metals in toy manufacturing are expanding, providing designers

with more creative freedom than ever before.

Laser Engraving:

Elevating Wheel Dynamics

Laser engraving plays a pivotal role in revolutionizing toy

car wheel design. This technique goes beyond aesthetics, contributing to

enhanced wheel dynamics and performance. Laser-engraved patterns on toy car

wheels can improve traction, create realistic tread patterns, and optimize the

overall functionality of the miniature vehicles.

The precision and accuracy of laser

engraving ensure that every detail is replicated consistently across each

toy car wheel. This attention to detail not only improves the performance of

the toys but also adds an extra layer of realism that appeals to both

collectors and young enthusiasts.

The Future of Toy Car

Design

As precision mould texturing continues to evolve, the future

of toy car design looks promising. Manufacturers are embracing advanced

techniques, collaborating with mould surface textures service providers, and

leveraging laser printing on metals and laser engraving to create toy cars that

not only capture attention on the shelves but also provide an unparalleled

playing experience.

The intersection of aesthetics and functionality in toy car

design is reaching new heights, thanks to the precision and innovation brought

about by these advanced technologies. Toy cars are no longer simple playthings;

they are miniature works of art that reflect the craftsmanship and dedication

of those shaping the future of the toy manufacturing industry.

Comments

Post a Comment